Drive Cycles in VCM Editor: What are they?

Published on: January 21, 2013Categories: Uncategorized

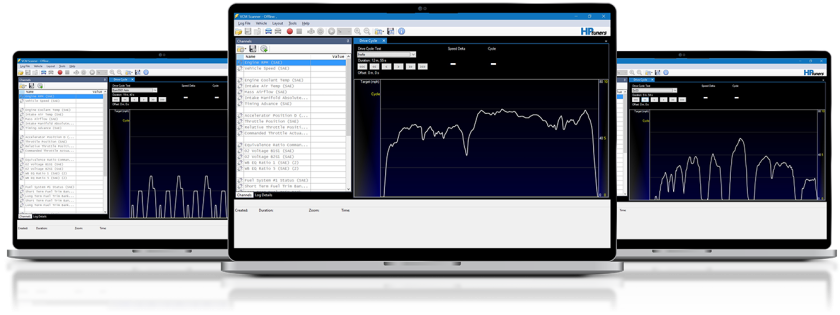

Drive Cycles are standardized driving patterns used to evaluate emissions and fuel economy. VCM Scanner’s Drive Cycle panel guides you through these procedures in real time so you can validate calibrations, confirm monitor readiness, and document results—perfect for shops and dealers developing emissions‑compliant products.

Why Drive Cycles Matter?

Modern tuning isn’t just about power—it’s about predictable behavior under standardized conditions. When you run an official drive cycle, you can:

- Verify on‑board diagnostics (OBD) monitors complete after service or calibration changes.

- Reproduce the same test conditions for A/B comparisons during R&D.

- Build a documentation trail that supports emissions‑compliant product development.

Note: Final emissions compliance must be determined in a certified laboratory. VCM Scanner’s Drive Cycle panel is a powerful tool for R&D and pre‑test verification.

What You Can Do in VCM Scanner

VCM Scanner includes a dedicated Drive Cycle panel (VCM Suite 4.13+):

- Follow a target speed trace in real time (white line = target, green line = vehicle speed).

- Stage‑by‑stage guidance for acceleration, deceleration, and steady‑state holds.

- Integrated logging so you can review trims, lambda, spark, catalyst temps (if available), misfire counters, and more.

Readiness check in Diagnostics & Information -> Emissions Monitors after the cycle.

Quick Start (Step‑by‑Step)

Connect & Prepare

- Use your MPVI interface and open VCM Scanner (close VCM Editor if open).

- Load a layout that includes the Drive Cycle panel.

Select the Drive Cycle

- Open the Drive Cycle panel and pick the required procedure.

- Keep engine cool prior to starting if your test requires it.

Start Scanning

- Key ON, connect, then Start Scanning.

Follow the Trace

- Match your speed to the on‑screen target. Transitions should be smooth and on‑time.

Verify Readiness

- After completion, open Emissions Monitors to confirm which monitors set.

Save your log and notes with the calibration revision.

Best Practices

- Control variables: Use consistent fuel, test weight, tire pressure, and ambient conditions across runs.

- Warm-up logic: Some monitors require specific coolant/oil temperatures—plan your pre‑conditioning accordingly.

- Channel selection: Log airflow modeling channels, STFT/LTFT, commanded and measured lambda, spark, catalyst temps (if equipped), and misfire/cylinder contribution.

- Repeatability > luck: Re‑run the same cycle after each calibration revision so you can isolate cause and effect.

- Document everything: Attach the log, notes, and calibration ID to your internal R&D record for traceability.

Integrate with MPVI4, RTD & TDN

If you’re standardizing an emissions‑focused workflow, pair VCM Scanner with MPVI4 for data acquisition and control, then manage customer devices and file delivery through RTD and TDN.

For approved partners, the Private Label RTD program offers a fully branded Remote Tuning Device and a streamlined way to submit calibrations for EO consideration, while Tune Delivery Network (TDN) simplifies customer management and update distribution.

FAQ

Does this certify my calibration?

No. Only certified lab testing can determine emissions compliance. VCM Scanner’s Drive Cycle panel supports your R&D and documentation.

Which vehicles are supported?

Coverage varies by controller/vehicle. If the Drive Cycle panel is present in your layout, select the appropriate cycle and confirm behavior using the Emissions Monitors view.

Which VCM Suite version do I need?

Drive Cycle panel is available in VCM Suite 4.13+. Update to the latest VCM Suite for the best experience.

Ready to Check Out Drive Cycles?

Open VCM Scanner, load the Drive Cycle panel, and run a guided cycle on your next calibration. Use MPVI4 for scanning and logging, and—if you support customers remotely—leverage RTD and TDN to deliver and manage calibration files efficiently.

If you’re interested in learning more, utilize our Help Center, Forum, Educational YouTube videos, or reach out to our technical support team.