Hi Guys,

This one has me stumped, need all the help I can get please.

Background: car is a 2004 M6 GTO with a Procharged (P1SC-1) 403CI. Custom CNC AFR 235 heads by Ed Curtis, Ed Curtis cam 224/232 .600/.600 114LSA, Wiseco coated pistons 9.25:1 SCR, Rhoads lifters,Callies crank, Compstar rods, LS6 intake, TR 6 plugs gapped to .035, New firecore 50 plug wires, Devils own Meth, squirting a 75% meth mix through 1 7GPH and 1 3GPH nozzle, with an additional 1 GPH nozzle precompressor, JBA shortie headers, flowing thru catless mids and a 2.5" Magnaflow exhaust.

My issue is that I can't seem to get any power beyond 5500RPM? I had similar issues with my old 408 setup which did share several components above...ie Crank, Rods, Cam, Lifters, all engine sensors etc....

With the new 403 installed I took the car to Dynamic Tuning Solutions...AKA EC_tune AKA Dougfor the initial dyno break in and tune. Car only put out 450 HP and was really unhappy about reving much beyond the 5K mark. Took the car home ran a couple of diagnostics and found both Cats were blown

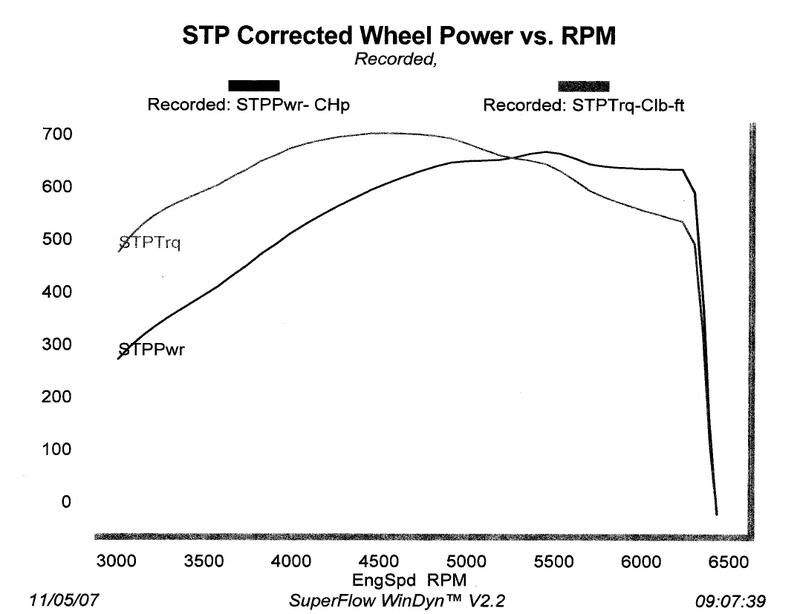

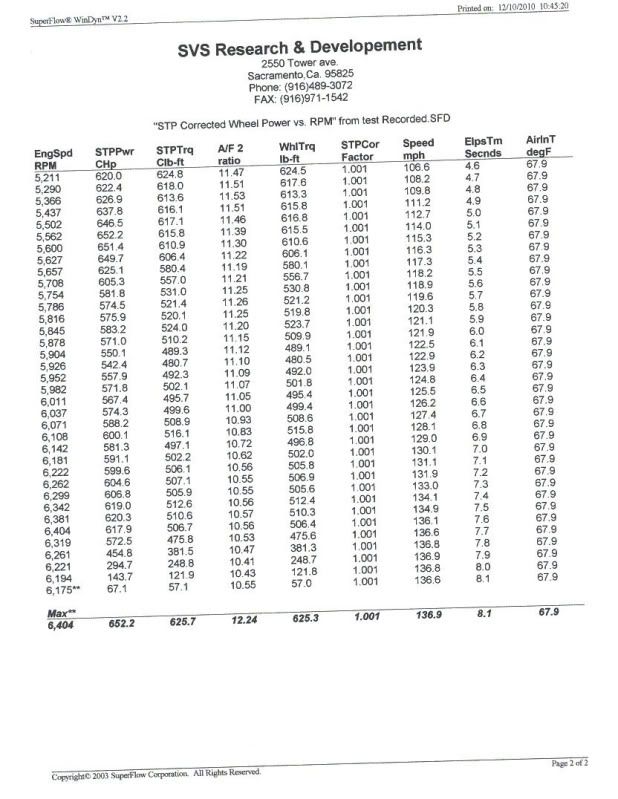

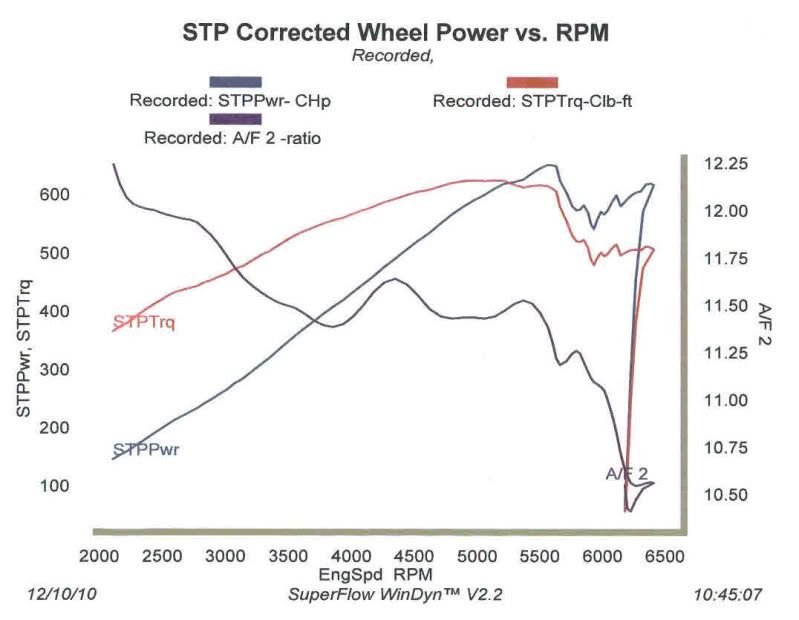

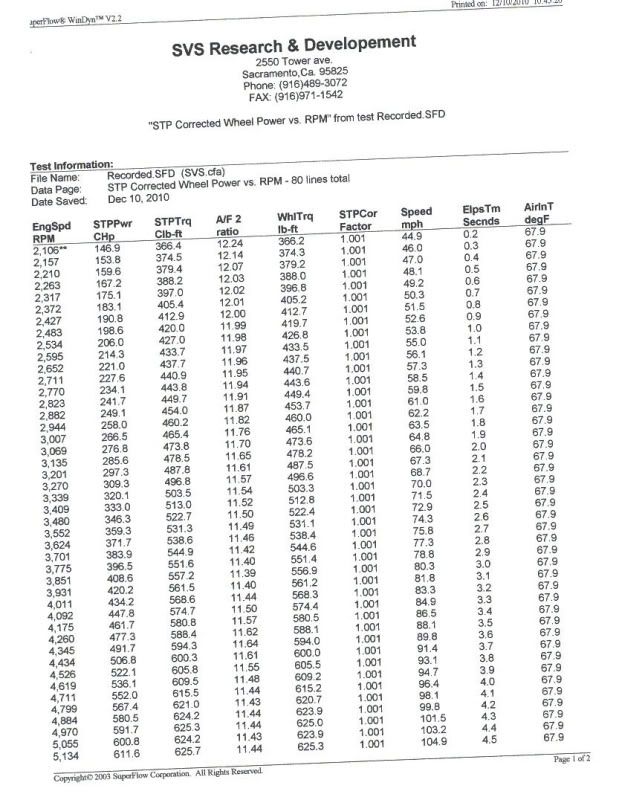

Installed a pair of Catless mids (for tuning purposes) and started on a "street tune" all seemed well and good, seat of the pants and HP tuner logs looked great. having tuned all I could with 3rd gear "on ramp" pulls, we put it on a superflow dyno this morning. The results were disappointing, although I have gained 200HP from where Doug left off, I still am not getting any linear movement past 5500 RPM?????

and no DTC's to help pinpoint any issues???

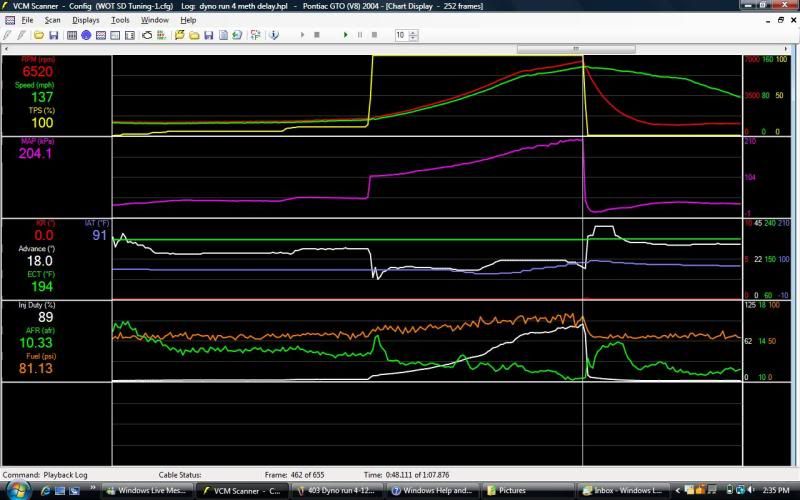

Today's first pull was just under 600 HP, I adjusted the meth controller to delay max Meth flow from 10PSI to 15PSI. This seemed to have helped as HP jumped to the best of the day 652 RWHP. My logged LC1 was showing 10.3 AFR while the tail pipe sniffer showed 10.5..I wouldn't think that was too rich to put the fire out in the holes....but maybe that is part of the issue?? I plan on turning the Meth off, putting the timing back in that Doug had initially and see if that at least lets the motor pull throughout the RPM range.

Given that I have similar issues with two different engines and completely different valvetrain top end...ie heads, springs, rockers etc. could it possibly be sensor or electronics related? could crank or cam shaft information be good up to a certain RPM then change???

In any case I am stumped, looking for all the help I can get. I hope this doesn't turn into a reluctor wheel issuenext worse case would be the Rhoads lifters, anyone heard of those being an issue at RPM???

The attached files are the current tune and dyno scan.

Reply With Quote

Reply With Quote