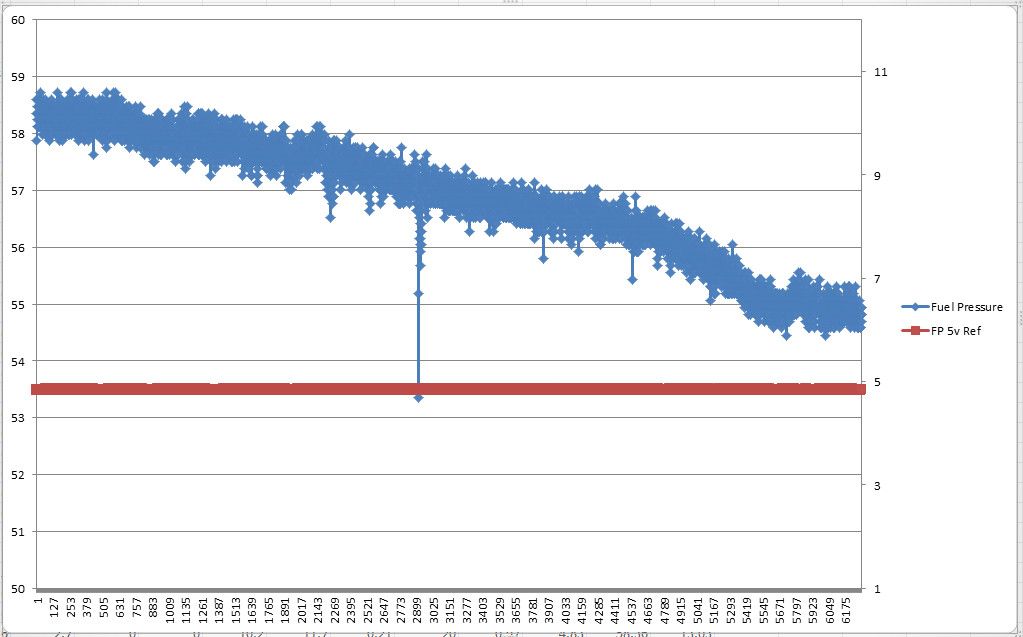

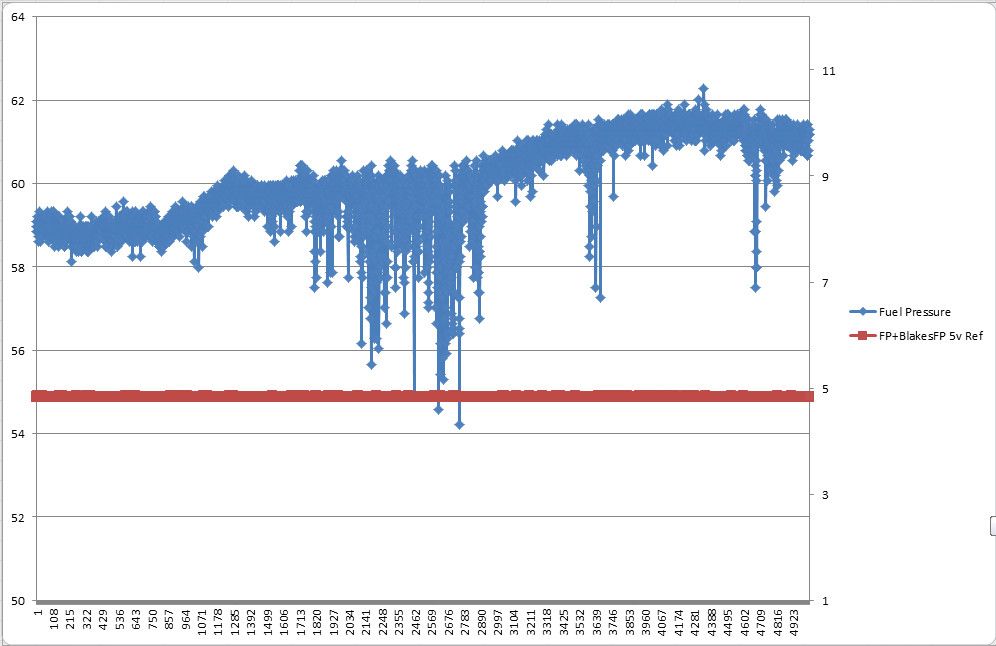

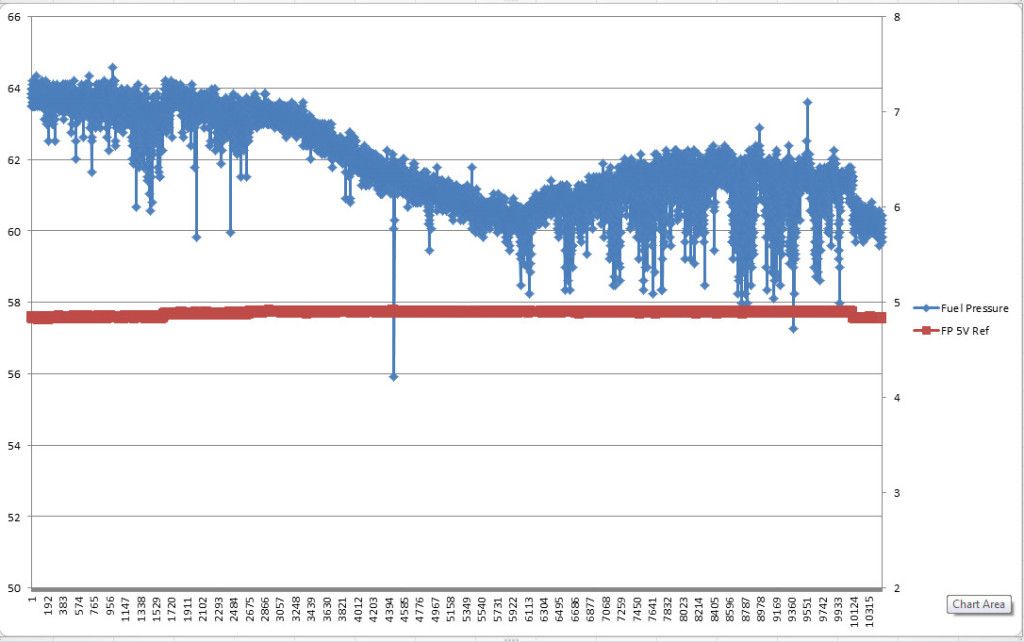

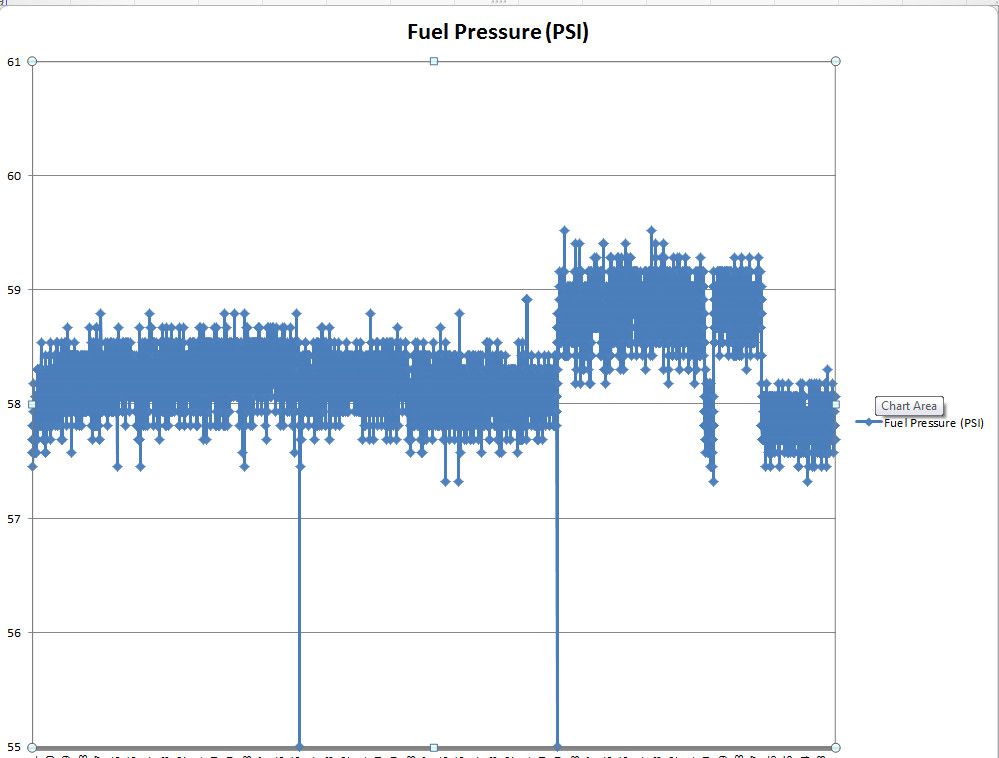

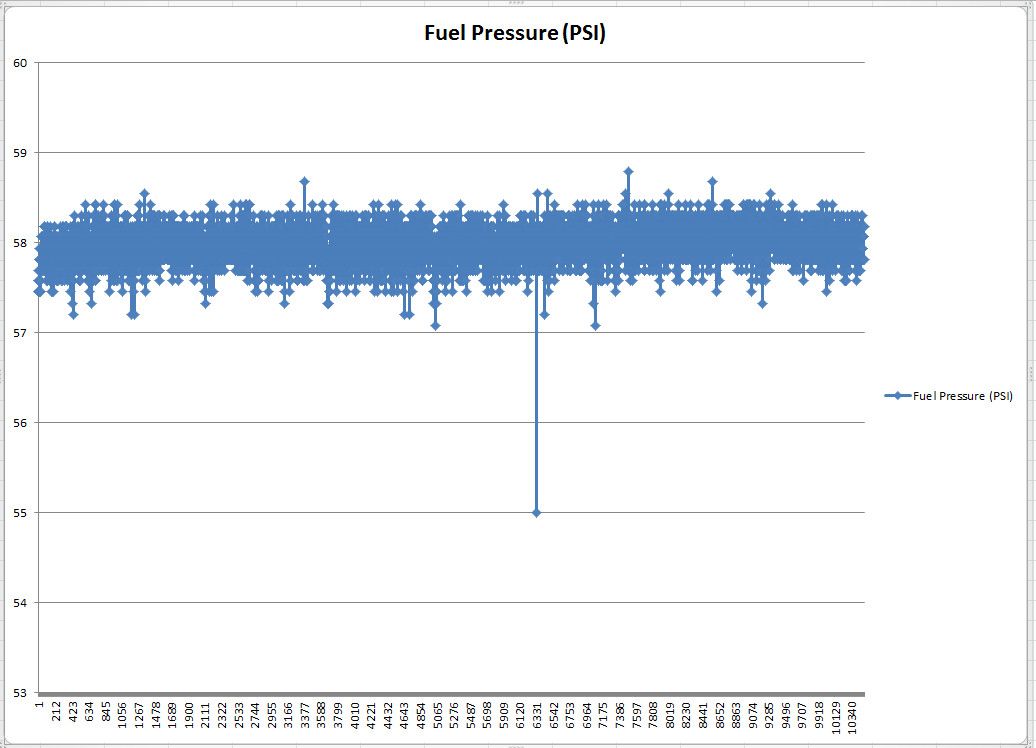

I would pull the pressure sensor from the rail and place it in the regulator to take out that surge of fuel on each injector pulse to see if that stabilizes your readings any. You also have to take into consideration fuel temp, engine bay temp, vibration etc.

LS1's don't normally come with pressure sensors so logging fuel pressure for me has been limited to those particular setups that someone actaully has installed one. My personal car doesn't fluctuate much that I've noticed... but that is reading a physical gauge and not logging it with a sensor such as yours.

Reply With Quote

Reply With Quote

I'd rather get a thrashing and some answers then no answers at all. Yes, I agree, FP logs or people that have logged FP are few and far between. Its another reason I think I'm overthinking this whole thing and I'm probably chasing something that isn't a problem at all. I'd just like to 'know' it's not a problem if you know what I mean.

I'd rather get a thrashing and some answers then no answers at all. Yes, I agree, FP logs or people that have logged FP are few and far between. Its another reason I think I'm overthinking this whole thing and I'm probably chasing something that isn't a problem at all. I'd just like to 'know' it's not a problem if you know what I mean.