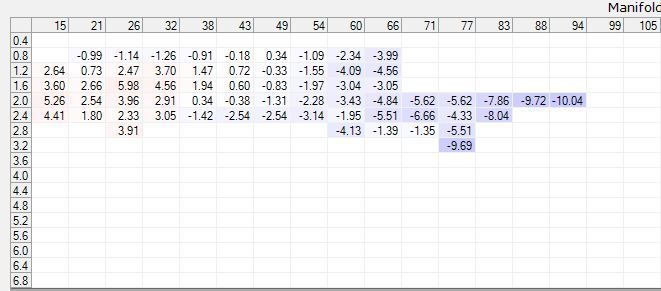

I need some help. I have thrown ridiculous money to tuners and on parts to fix this but still no resolution. I keep on getting knock retard. It seems KR is most prevalent when throttle is greater than 40% but it's also kind of random, it does not matter if it's in PE or running stoich, i get KR. I'm running 93 octane and this has been happening for a while regardless of where I gas up.

Mechanically speaking here's what I've done & checked

- Stepped up to 7.425 pushrods to quiet down valve train. Measured /verified length on ea pushrod with tools (now running .60xx preload)

- Replaced 1 knock sensor (original looks fine, wiring looks good to both sensors)

- Changed fuel filter

- Upgraded to AFR500 wideband AKA ?NGK AFX?

- A few valvestem seals unseated a while ago. All have been replaced and verified good

- Engine Seafoamed afterwards (brake booster method) although borescope only showed minor carbon deposits if any

- Fuel injector cleaner has been pushed through the system

In regards to the tune, the new wideband says i have been pretty dialed in with the exception of startup and first 30 sec of driving? Everything else looks good in the tune IMO. My wideband is connected to A/C press sensor. Custom PID = 9+[PID.7101]*1.400 (according to BMR motorsports site). PS it?s also calibrated. And yes, VVE tables are tuned properly too.

I don't see any smoking guns and I desperately need your help. I'm tired of driving like a grandpa to avoid KR. My timing is pretty much stock too. Please help!!!

Car specs

2006 CTSv

Stock LS2 w/ stg 1 tick performance cam

longtube headers

LS7 clutch

NGK TR5IX plugs

Reply With Quote

Reply With Quote