Is there a no bullshit way to setup HPtuners pro for the Innovate LC-1 wideband sensor?

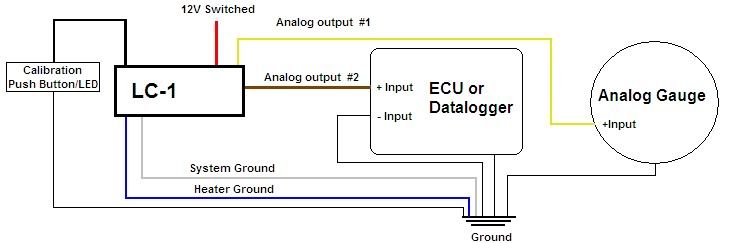

I have done a search and read just about all the threads concerning the LC-1 but not one truly answers the right way to set everything up for the LC-1 to work with HPtuners pro. Can anyone help me out? I am aware that you take the LC-1 analog output #2 wire and connect it to the EIAO input 1 or 2 or 3 or 4 in HPtuners but beyond that I am not sure what forumula you use in HPtuners software for the offsets to make sure its accurate. Any help is appreciated.

Reply With Quote

Reply With Quote