Why are nearly all spark maps level at high load/rpm?

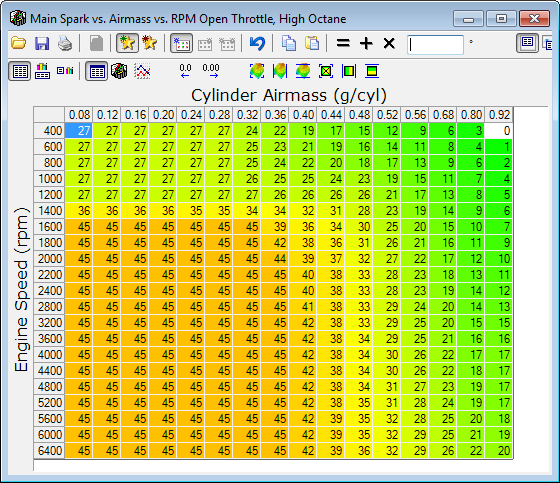

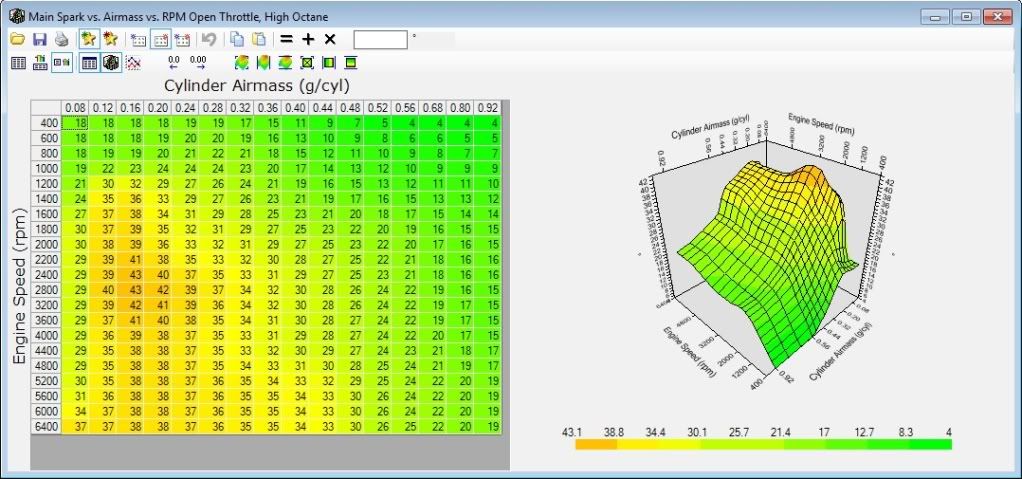

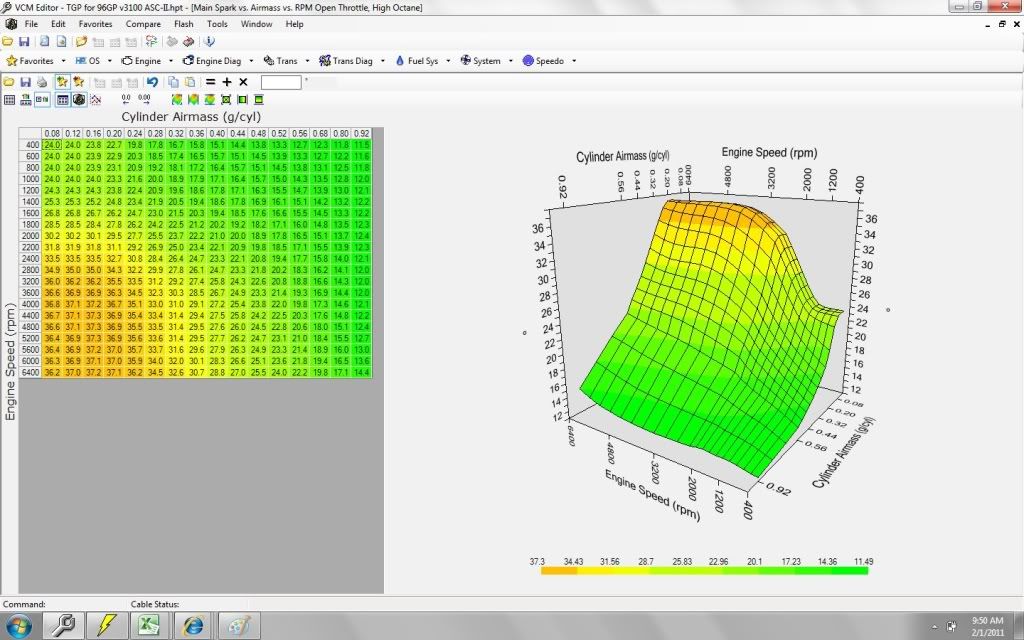

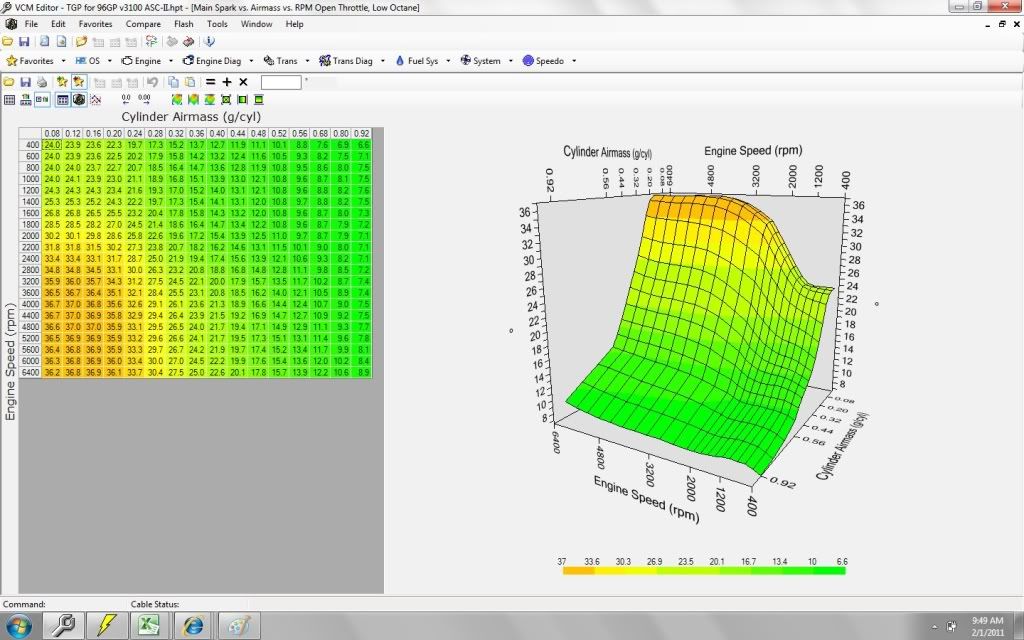

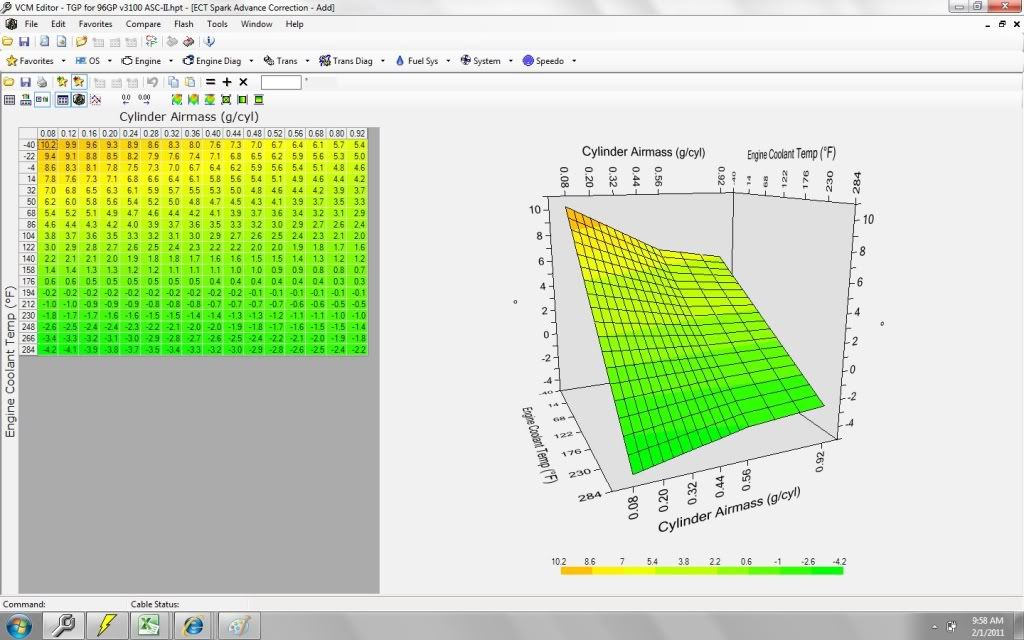

My GP Spark Map ranges from 17-20 degrees advance at 0.92 g/cyl (3600-5600 RPM). This seems just fine except for the math.

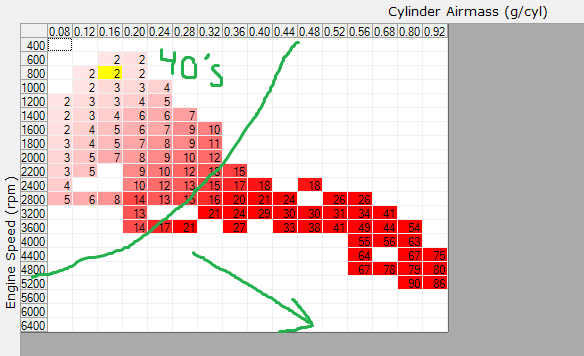

As RPMS increase the flame speed still remains the same resulting in timing having to become gradually more advanced as rpm's rise. The math doesn't add up.

Point example:

3600 rpm at 18* BTDC advance with optimal peak pressure at 12* ATDC. Rotating 30 degrees at that rpm takes 1.388889 ms. So this is a good reference time for burn time to peak pressure, 1.388889 ms. As I know my engine runs great at these settings.

But at 5200 rpms one needs an advance of 31.33 degrees BTDC to hit 12* ATDC in 1.388 ms. As the flame front takes roughly about 1.3 ms to reach the piston at an AFR of 13.7:1

This is what confuses me about the Stock Spark Maps. Are these maps that generalized and thus horribly inaccurate or .....what am I missing?

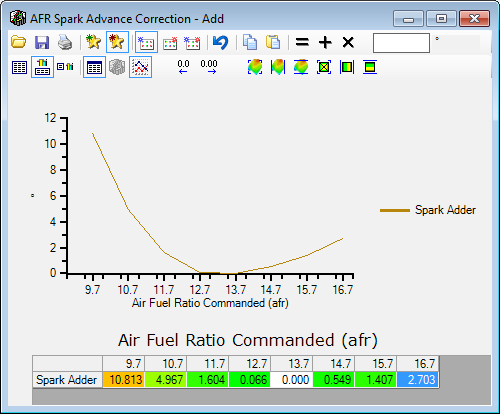

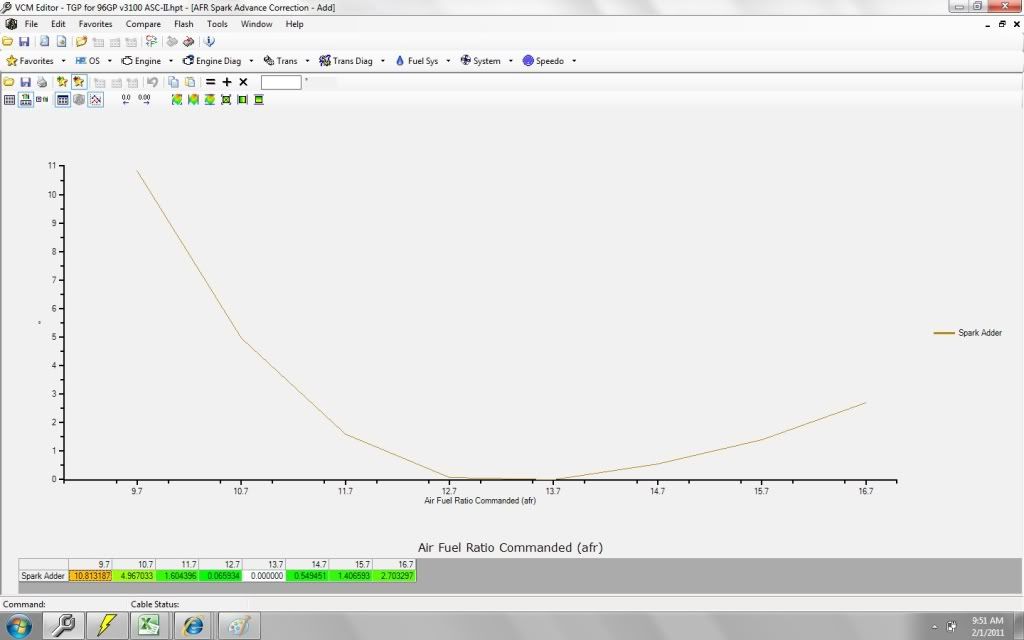

I even calculated the speed of flame front per AFR.

10:1 = 330 mm per sec

11:1 = 380 mm per sec

12:1 = 413 mm per sec

13:1 = 425 mm per sec

14:1 = 423 mm per sec

15:1 = 415 mm per sec

16:1 = 402 mm per sec

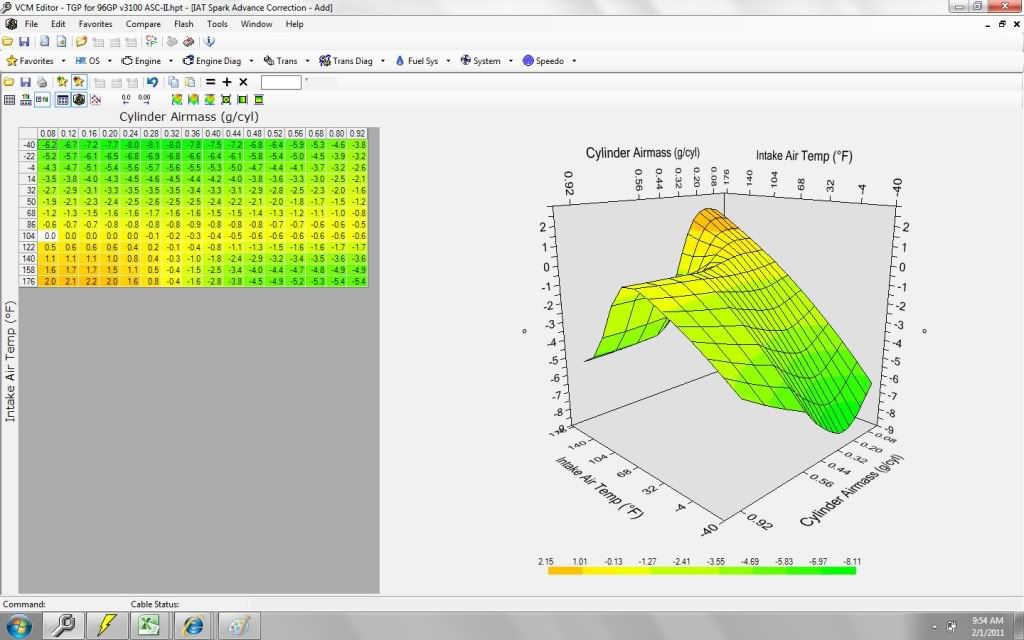

What about airmass and its effects on flame front speed?

Reply With Quote

Reply With Quote