it really doesnt matter in the higher rpm because of how fast the engine is running . at 80% dc or even 51%, the injector is open more than its closed (greg has said this). the issue at hand is low rpm injector timing where getting the fuel to mix as best is possible without losing any thorugh the exhaust is the whole name of the game.

for 1000-3400 rpm you are running in a very predictable area in terms of manifold pressure anyways.

it would matter (though not much more) in the later ecms where you can adjust according to rpm and not ect.

since u said it was closer to .006" lift that the gains occured, heres mine on the torquer 2 i have:

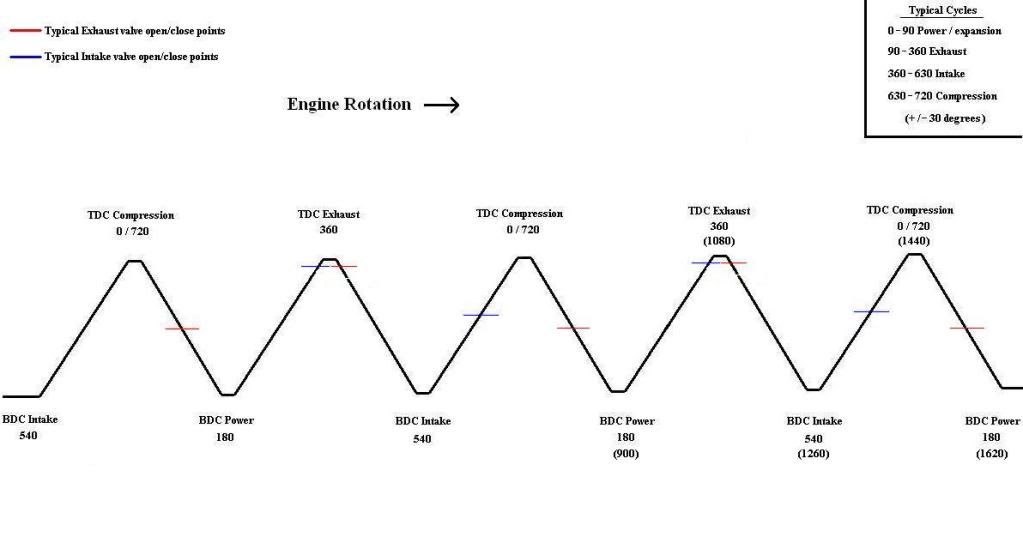

IVO is 30.5 ° BTDC ( - indicates ATDC)

IVC is 70.5 ° ABDC

EVO is 77.5 ° ATDC ( - indicates BTDC)

EVC is 25.5 ° BBDC

Reply With Quote

Reply With Quote