1996 Grand Prix SE

PCM: 97 Lumina for HPT support

Turbo: TO4E .50/.63 @ 9 psig

Spool Up: 2800-3800 rpm's

Throttle Body: 52mm (ported to 58mm equivilant)

*IAC Steps remain at 35

Injectors: 36lb SC 3800v6

Gas: Pump 93 with up to 10% Eth (true stoich is @14.25:1)

Ported Heads, Pocket Smoothing, Gasket Matched, Valves Deshrouded, Exhaust Smoothed and Polished.

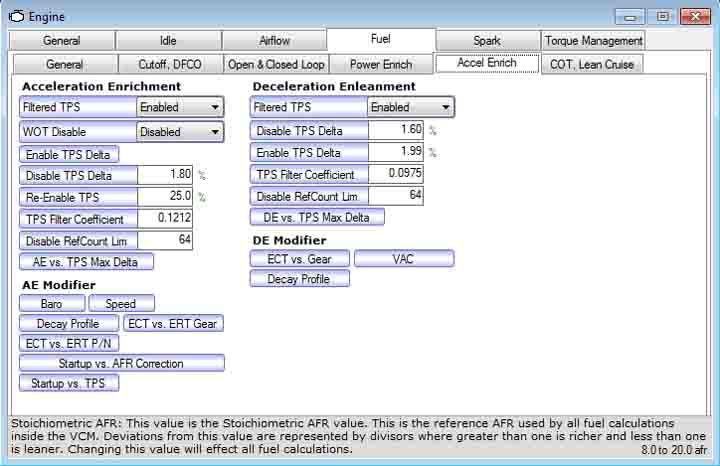

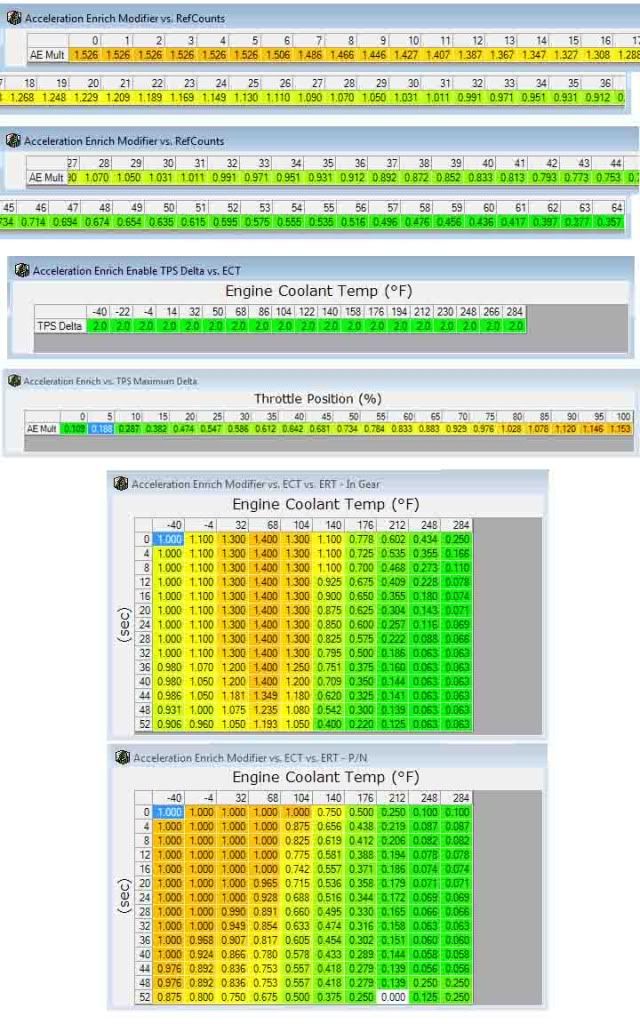

How does one go about fine tuning the AE parameters?

What are the basics, as in...?

What table do I generally make the AE richer or leaner?

What do you guys do to get the AE in tune?

Should I Increase the AE vrs. TPS Max Delta table by multiplying 1.01 and decrease by 0.99 as often as needed to adjust?

Is there any trick like, getting a dead spot when snapping the throttle, increasing some setting until the dead zone disappears?

Could I command a steady AFR in PE mode at idle (stoich) and get a better reading of AFR snapping rich or lean?

I understand a proper AE can make a big difference in take off. Seems like a very important setting for 1/4 mile times. Any delay at the snap of the throttle is just a big waste of time and we know how that can impact 1/4 mile times.

So if anyone wants to get technical, please do. I can handle some serious math or logging. I considered logging only the NBO2 to gain greater resolution but I haven't read anyone doing that so I wonder if it a feasible application of the scanner or is it pointless?

Also, I am pushing 9-10 psi of boost. Boost starts at 2800 rpm and peaks at 9psi at 3800 rpm. So far I haven't had any lack of airflow at 5500 rpm's so the turbo can handle the airflow just right. T04E .50/.63 trims works great for the 3100v6 small port.

Reply With Quote

Reply With Quote